Having said that, it is important to note that among all packaging types, the auto bottom boxes are particularly popular because they are a versatile, strong, easy-to-assemble option. Your customized boxes can enhance the overall position of your brand or those of an auto manufacturer to improve the former’s appeal and packaging performance.

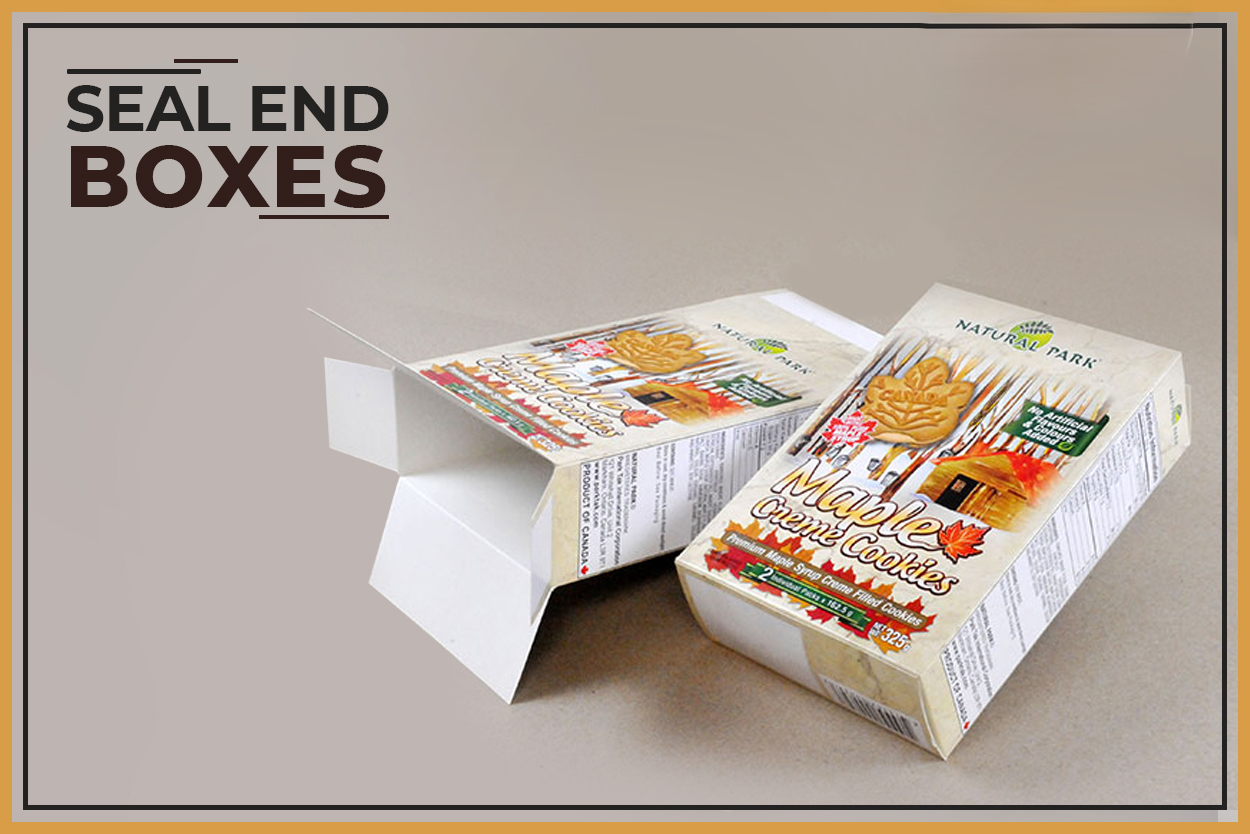

This article intimately focuses on the best practices for customization of a custom seal end auto bottom boxes and how it can help in product packaging and branding, especially in such a competitive market environment.

High-Quality Material

Packaging material is one of the main aspects determining the overall quality of the product. It is thus imperative to use high-quality cardboard or other cardboard materials with high levels of corrugation not only for product protection but also as a reflection of the fact that you care about quality. It is also necessary to use eco-friendly materials for the client’s choice and promotion of sustainability, corresponding to the environment-friendly views of the clients.

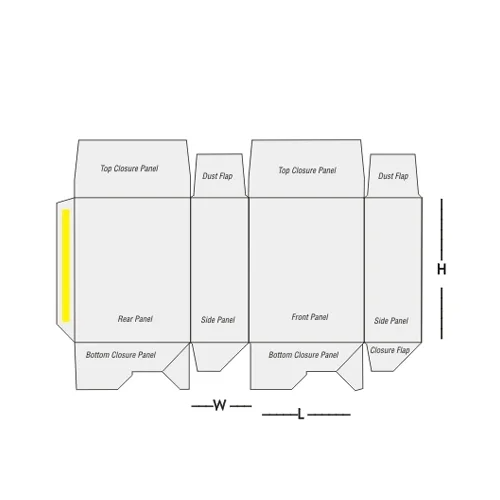

Precision in Dimensions

The one-fits-all strategy for packaging is not the ultimate solution. The use of seal end auto bottom boxes with logo makes the items better if the dimensions are precise such that they fit the product in question without having to leave excessive space or leaving it compressed in between the sides of the box. Measurement methods also keep the amount of material needed at the minimum, thus doing more in the shipping process without having to pay too much.

Measuring Your Product

Use precise measurements to capture the dimensions of your products including length, width, and height as well as shapes that may affect the design of the box like the design of the angle of the box. The release of complete specifications allows the packaging supplier to develop tailor-fit solutions that can be specifically designed to the sizes and shapes of products.

Branding and Business Slogans

Custom seal end auto bottom boxes are a great packaging solution where maintaining brand identity is significant for long-term brand recognition. Partner with some graphic designers to incorporate the logo, brand color and image in such a way that they do not fade into the paper that makes up the packaging. Upgrading your printer or opting for a trusted offset or digital printing process guarantees sharper, captivating images that appeal to your target group.

Functional Features

Seal-end auto bottom boxes are not limited to a simple discretionary approach to functionality. Comment on that by suggesting incorporating functional elements like clear glass or hoes to increase the excitement of the buying process. The use of transparent windows forces the consumers to view the enclosed product, while handles enable mobility for food products as well as heavy products.

Types of Functional Features

Following are some types of Custom seal end auto bottom boxes and their uses:

Transparent Windows

Suitable for displaying items like food and bakes, beverages and confectionery as well as cosmetics hence helping consumers in identifying the desired products.

Handles

Especially useful for larger or heavier products, handles add value to products for people who may need to move them from one place to another; providing a further level of safety for users to ensure it does not easily slip out of their hands.

Unboxing Experience.

A superior unboxing is arguably the best way to set an emotional connection with consumers as it creates brand recognition and enables customers to become brand ambassadors. Remember to decorate the unboxing journey with premium custom boxes in UK insert; tissues or personal notes inside the seal-end auto-bottom boxes. In addition to both enhancing the perceived value of products and creating the feeling of affection for the product, these can also promote attachment to the brand between consumers and your brand.

Fatigue Testing Explanations

The most recommended tests include drop tests, compression tests, and environmental simulations that should be used to test the ability of the box to deal with handling, transporting, and storing the box. Despite being a significant cost to the firm’s balance sheet, proper testing ensures the product’s quality and reduces the likelihood of product failure or customer dissatisfaction. Hence, Custom seal end auto bottom boxes are the most suitable example for these kinds of boxes.

Types of Tests

Drop Test

Effectively test the box’s ability to withstand impacts and shocks by using a drop test from different heights.

Compression Test

Determine the stacking strength of the corrugated board to determine valuable product protection against crushing pressure.

Environmental Test

Temperature cycling and humidity changes will be applied to the box to test its handling of various conditions.

Conclusion

To achieve the best Custom seal end auto bottom boxes through the use of seal end cases it would be good for the user to carefully consider the material to be used, the design elements, the functional features, and the finish. These are some of the guidelines from experts on how you can design packaging that is not only protective but also helps you shape the positive image of your brand and convince your customers. To guarantee that your sealed end boxes are made just the way you want them, it is best if you go for a packaging supplier that you can trust.

Read More: https://blooketlogin.pro/