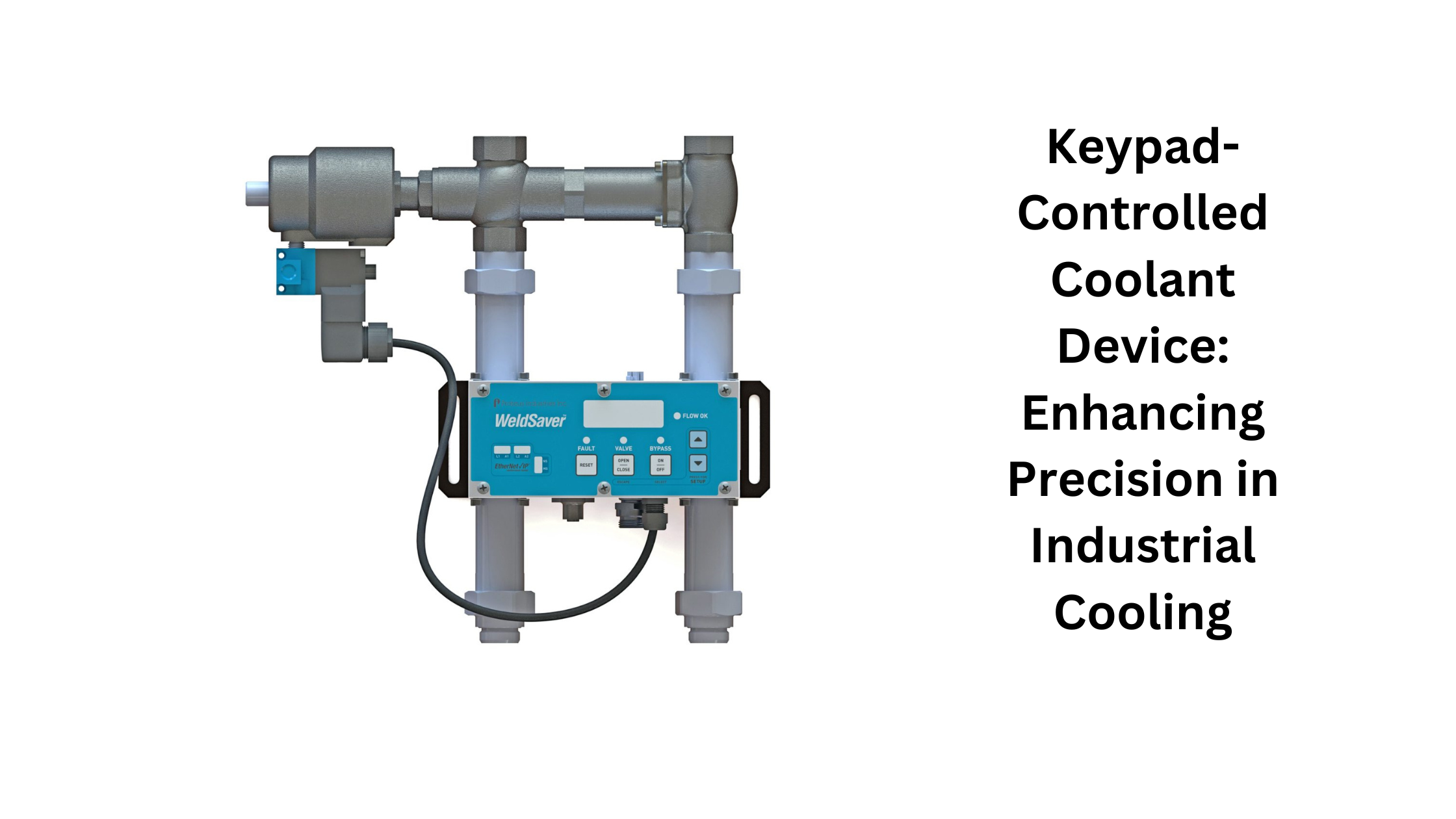

In industrial processes where precision and reliability are paramount, the advent of the keypad-controlled coolant device by Proteus Industries Inc. marks a significant leap forward. This advanced system provides unmatched control and monitoring capabilities designed specifically to meet the rigorous demands of contemporary manufacturing environments.

Introduction

Coolant management is critical to industrial operations, particularly in sectors where maintaining optimal temperatures is crucial for equipment performance and product quality. Traditional coolant systems often lack the precise control to adapt quickly to varying operational conditions. Enter the keypad-controlled coolant device from Proteus Industries Inc., designed to address these challenges with innovative features and user-friendly functionality.

Key Features and Benefits

- Precision Temperature Control: The keypad-controlled coolant device allows operators to set and maintain precise temperatures, ensuring consistent performance and enhanced product quality.

- User-Friendly Interface: The intuitive keypad interface will enable operators to easily input and adjust settings without extensive training or technical expertise.

- Remote Monitoring Capabilities: With integrated remote monitoring, supervisors can track coolant system performance in real time, enabling proactive maintenance and minimizing downtime.

- Customizable Settings: Flexible programming options allow customization based on specific operational needs, seamlessly accommodating diverse industrial applications.

- Safety and Reliability: Built with robust features, the device prioritizes operational reliability while safeguarding against potential hazards, enhancing workplace safety standards.

How It Works

The keypad-controlled coolant device operates by interfacing with existing coolant systems, leveraging advanced sensors and actuators to regulate coolant flow and temperature according to preset parameters. This automated approach optimizes efficiency and reduces manual intervention, streamlining production processes.

Additional Benefits

- Energy Efficiency: The device helps optimize energy consumption by maintaining precise coolant temperatures, reducing operational costs and environmental impact.

- Data Logging and Analysis: Integrated data logging capabilities enable detailed analysis of coolant system performance trends, facilitating informed decision-making and continuous improvement.

- Compatibility and Scalability: Designed to integrate seamlessly with various industrial setups, the device supports scalability as production needs evolve, ensuring long-term reliability and adaptability.

- Maintenance Alerts and Predictive Diagnostics: Proactive and predictive maintenance alerts preemptively identify potential issues, minimizing unplanned downtime and maximizing operational uptime.

Conclusion

In conclusion, the keypad-controlled coolant device by Proteus Industries Inc. represents a significant advancement in industrial cooling systems. By integrating precision control with user-friendly interface design, Proteus Industries .inc has addressed critical needs in various industrial sectors, from manufacturing and processing to research and development.

The device’s ability to accurately regulate coolant flow and temperature enhances operational efficiency, cost savings, and productivity. Industries relying on precise temperature control, such as semiconductor manufacturing, medical device production, and aerospace engineering, stand to benefit significantly from this innovation.

FAQs

- What are the primary advantages of using a keypad-controlled coolant device?

- The device offers precise temperature control, ease of use, remote monitoring, and customizable settings tailored to industrial needs.

- Can the keypad interface be customized for specific user preferences?

- Operators can easily adjust settings and programming to suit varying operational requirements.

- How does remote monitoring enhance operational efficiency?

- Remote monitoring allows supervisors to track real-time performance metrics, enabling proactive maintenance and minimizing downtime.

- What safety features are integrated into the device?

- The device includes robust safety protocols to ensure operational reliability and enhance workplace safety standards.

- Is the keypad-controlled coolant device compatible with existing coolant systems?

- Yes, it seamlessly integrates with most industrial coolant systems, enhancing their functionality and performance.

- Can the device be programmed for automated operation?

- Yes, it supports automated operation through programmable settings, reducing the need for constant manual adjustment.

- How does the device contribute to energy efficiency?

- The device helps optimize energy consumption and operational efficiency by maintaining precise coolant temperatures.

- Does Proteus Industries provide technical support for installation and maintenance?

- Proteus Industries offers comprehensive technical support services for installation, training, and ongoing maintenance.

- Where can businesses procure the keypad-controlled coolant device?

- Businesses can contact Proteus Industries directly or visit their website for purchasing information and product details.