Introduction to Air Cooled Heat Exchangers

Air-cooled heat exchangers are integral components in many different industrial procedures. They provide a reliable method of cooling fluids with no need to utilize water. The capability of these units to disperse heat with the natural air will enable them to be highly effective in various industries, including chemical processing and power facilities. This blog is focused on the building and use as well as the benefits of air cooled heat exchangers, and the interactions they have and interactions with Nash vacuum pumps using liquid rings.

Understanding Air Cooled Heat Exchangers

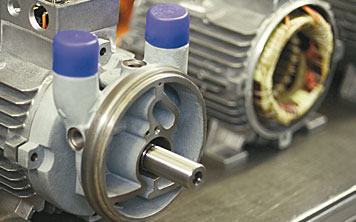

Air-cooled heat exchangers work by their transfer of heat that is generated from the fluid to the air around it. They consist comprising finned tubes on which the fluid circulates. The fan pushes air across the fins which absorbs heat from liquid, before distributing it into the surrounding air. This means that there is no need for an additional cooling source of water. These heat exchangers that are air-cooled are suitable for places where water supply is costly or scarce.

Benefits of Air Cooled Heat Exchangers

- Water Conservation: The main benefits of air-cooled together heat exchangers is that they can minimize the usage of water. Contrary to traditional cooling systems which rely heavily on water supplies exchangers use air to cool the air for water consumption as well as the expenses related to the usage of it.

- Environmental Friendlines: Green to cut out the need to cool air or water and heat exchangers air-cooled reduce environmental harms that result due to water usage and removal. They are greener options to cool systems.

- Effectiveness: The use of heat exchangers with air cooling could drastically reduce the cost of operation through the elimination of the need for water treatment and reduction in repairs. The long lifespan of their services can benefit save you money.

- Versatility and Flexibility: The adaptability and flexibility of these units can be used for a range of uses, and adapt to a wide range of industrial processes. The design of these units permits easy installation as well as integration into current processes.

Applications Across Industries

Air-cooled heat exchangers are able to be used in numerous industries due to their effectiveness and adaptability. They are utilized in many applications. These include:

- Power Generation: At a power plant, air-cooled heat exchangers are used to cool steam and other fluids. This boosts energy production as well as reducing the consumption of water.

- Chemical Processing: Chemical Processing using heat exchangers for cooling different procedures to ensure efficient temperature control in addition to streamlined process.

- Petrochemical Industry: The petrochemical industry heat exchangers that are air-cooled exchangers are found in the petroleum sector for cooling the hydrocarbon gas and liquids for increased process efficiency as well as security.

- Manufacturing: In factories, heat exchangers help cool machinery and equipment to prevent overheated and ensures that everything runs smoothly.

Integrating Nash Liquid Ring Vacuum Pumps

Nash Vacuum pumps for liquid rings typically are used with the air-cooled heat exchangers in order to boost the performance of the unit. They are essential in ensuring the necessary pressure differentials in order to propel flows of liquid in the tubes in the heat exchanger. In order to ensure optimal pressure conditions Nash liquid ring vacuum pumps are beneficial to increase the efficiency of heat transfer through heat exchangers with air cooling.

Environmental and Economic Benefits

Heat exchangers that are air-cooled are able to provide important benefits to the environment as well as to the economy. In addition to reducing water consumption, and lessening the need to treat it, they can cut operational costs and lower impacts on the environment. In addition they can help reduce power consumption. This further improves their financial sustainability.

Future Trends and Innovations

In a time when industries are putting the emphasis on sustainable development and effectiveness, the future of heat exchangers that are air-cooled is to be promising. Innovations are in progress with the aim of increasing the effectiveness of heat transfer, as well as decreasing energy use and enhancing the efficiency overall in exchangers. Innovations in the construction and material are expected to lead to less invasive and efficient exchangers.

Additionally, the introduction of advanced technologies and IoT (Internet of Things) capabilities that are expected to transform the maintenance process and monitoring air-cooled exchangers. In real-time, the collection of information, and the analysis of it could aid in determining maintenance requirements and also increase performance. This can reduce time between maintenance while also ensuring that the exchangers operate at maximum efficiency.

Conclusion

Air-cooled heat exchangers can be vital tools for use for a variety of industrial uses. They’re valued for the conservation of water and energy and energy consumption, their eco-efficiency, the affordable cost in addition to their versatility. The capacity they have to provide effectively cooling, without the use for water makes them the perfect choice in producing power along with chemical processing, petroleum chemicals as in manufacturing.

Together with Nash vapour rings, liquid pumps the effectiveness of heat exchangers that are air-cooled can be improved by providing that they have the desirable pressure conditions as well as maximizing the effectiveness of the transfer of heat. With the technological advancements, air-cooled heat exchangers will be able to become greener and more efficient. This can boost their value as vital elements in modern manufacturing equipment.

The advantages and benefits of heat exchangers that are air-cooled will greatly boost the effectiveness and effectiveness in industrial operations. By incorporating these advanced cooling solutions will impart higher thermal efficiency, energy conservation and lower carbon footprint. These devices are an ideal opportunity to boost industrial processes.