In the world of warehousing and logistics, space is money. Optimizing storage space can lead to significant improvements in efficiency and cost savings. This is where heavy-duty industrial racks come into play. They are the backbone of any well-organized warehouse, and understanding how they are made can shed light on their durability and effectiveness.

What Are Heavy-Duty Industrial Racks?

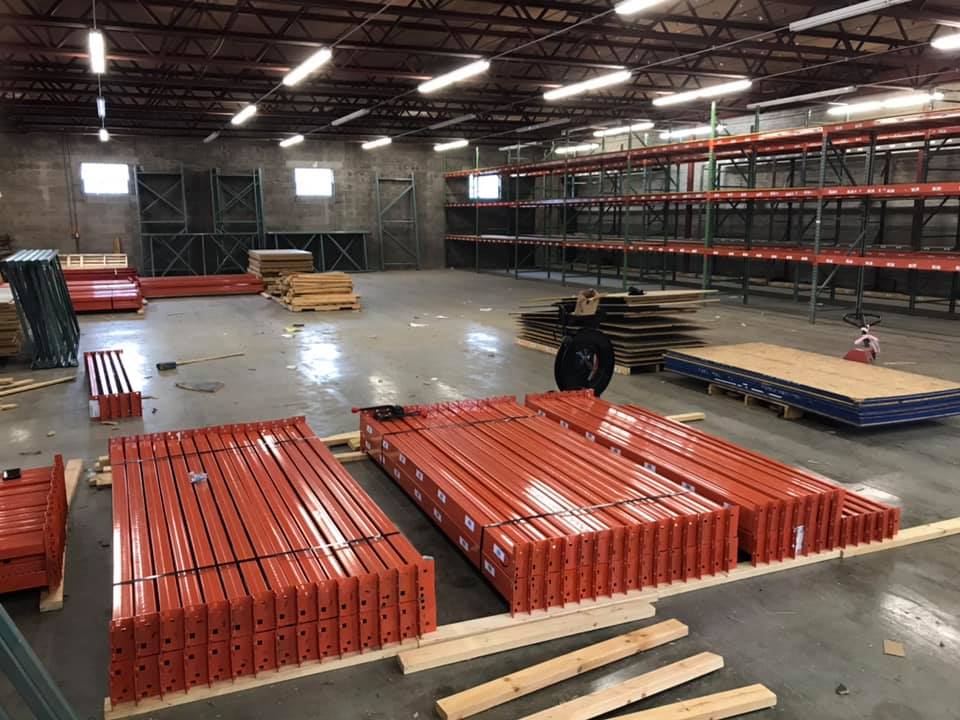

Heavy-duty industrial racks are robust storage solutions designed to hold substantial weight and withstand rigorous use. These racks are essential in various settings, from warehouses to manufacturing plants, where they organize and support large quantities of materials, products, and equipment.

The Importance of Heavy-Duty Industrial Racks in Warehousing

Maximizing storage space is crucial in any warehouse environment. Heavy-duty industrial racks allow businesses to use vertical space efficiently, freeing up floor space for other operations. This not only enhances the overall workflow but also boosts productivity by making it easier to access and manage inventory.

Materials Used in Manufacturing Heavy-Duty Industrial Racks

The strength and durability of heavy-duty industrial racks come from the high-quality materials used in their construction. Typically, these racks are made from various types of metals such as steel and aluminum. Steel is often preferred due to its superior load-bearing capacity and longevity. Additionally, racks are coated with protective finishes like powder coating or galvanization to prevent rust and corrosion, ensuring they withstand harsh industrial environments.

Designing Heavy-Duty Industrial Racks

Design is a critical aspect of heavy-duty industrial racks. Engineers consider factors such as load-bearing capacity, the type of items to be stored, and the specific needs of the facility. Customization options are also available, allowing businesses to tailor racks to their precise requirements, including adjustable shelving, special dimensions, and specific weight capacities.

The Manufacturing Process

Creating heavy-duty industrial racks involves several key steps:

- Cutting and Shaping Materials: Raw metal sheets are cut and shaped into the required dimensions using advanced machinery. This step ensures that each component fits together perfectly.

- Welding and Assembly: The cut pieces are then welded together to form the rack structure. Skilled welders ensure that all joints are secure, providing the necessary strength and stability.

- Finishing Touches: After assembly, the racks are coated with protective finishes to enhance durability and resistance to environmental factors.

Quality Control Measures

To ensure the highest quality, heavy-duty industrial racks undergo rigorous testing. This includes stress testing to verify load-bearing capacity and durability assessments to confirm they can withstand prolonged use. Quality control is a continuous process, with each rack checked at various stages of production to maintain consistency and reliability.

Innovations in Heavy-Duty Industrial Rack Manufacturing

The manufacturing of industrial racks has seen significant advancements over the years. Innovations in materials, such as high-strength alloys and composite materials, have enhanced rack performance. Technological improvements in machinery and automation have also streamlined the production process, resulting in more precise and efficient manufacturing.

Safety Considerations

Safety is paramount in the manufacturing and use of heavy-duty industrial racks. Ensuring structural integrity through careful design and rigorous testing is essential. Manufacturers adhere to strict safety protocols to prevent accidents and ensure that racks can safely support the intended loads.

Environmental Impact

As environmental concerns grow, many manufacturers are adopting sustainable practices. This includes using eco-friendly materials, reducing waste, and implementing energy-efficient manufacturing processes. These efforts not only benefit the environment but also appeal to eco-conscious consumers and businesses.

Cost Factors in Production

The cost of producing heavy-duty industrial racks depends on several factors, including the price of raw materials, labor costs, and the complexity of the design. While high-quality materials and skilled labor can increase costs, the investment pays off in terms of durability and performance.

Installation of Heavy-Duty Industrial Racks

Proper installation is crucial to the functionality and safety of industrial racks. The process begins with pre-installation planning, where the layout and design are finalized. Installation involves securing the racks to the floor and walls, ensuring they are level and stable. Following a step-by-step process guarantees that the racks are installed correctly and can safely support the intended loads.

Maintenance and Longevity

Regular maintenance is essential to prolong the life of heavy-duty industrial racks. This includes routine inspections to check for signs of wear and tear, as well as prompt repairs and refurbishments when necessary. Properly maintained racks can last for many years, providing reliable storage solutions.

Case Studies: Success Stories

Numerous businesses have benefited from the use of heavy-duty industrial racks. For example, a large distribution center improved its efficiency by 30% after installing custom-designed racks from Georgia Pallet Rack. Another manufacturing plant reported a significant reduction in product damage and better space utilization. These success stories highlight the impact of high-quality industrial racks on operational efficiency.

Conclusion

Heavy-duty industrial racks are a vital component of any well-organized warehouse. Their robust construction, innovative design, and customizable options make them indispensable for optimizing storage space and enhancing efficiency. By understanding how these racks are made in a heavy duty industrial rack factory, businesses can make informed decisions about their storage solutions, ensuring they invest in products that offer durability, safety, and performance.

FAQs

What materials are used to make heavy-duty industrial racks?

Heavy-duty industrial racks are typically made from high-strength metals like steel and aluminum, often coated with protective finishes to prevent corrosion.

How do heavy-duty industrial racks improve warehouse efficiency?

They maximize vertical storage space, freeing up floor space for other operations and making it easier to organize and access inventory.

What are the key steps in manufacturing heavy-duty industrial racks?

The process includes cutting and shaping materials, welding and assembly, and applying protective finishes.

How often should industrial racks be inspected and maintained?

Regular inspections and maintenance should be conducted to check for signs of wear and tear and to perform necessary repairs and refurbishments.

Can heavy-duty industrial racks be customized?

Yes, they can be customized to meet specific needs, including adjustable shelving, special dimensions, and specific weight capacities.