When it comes to construction or manufacturing projects, the quality of materials used is crucial. One such essential material is the square bar. Whether you’re building a structure, fabricating a part, or crafting a piece of furniture, choosing high-quality square bars can significantly impact the success and durability of your project. In this guide, we will explore five tips for selecting high-quality square bars to ensure your project stands the test of time.

Understanding Square Bars

What Are Square Bars?

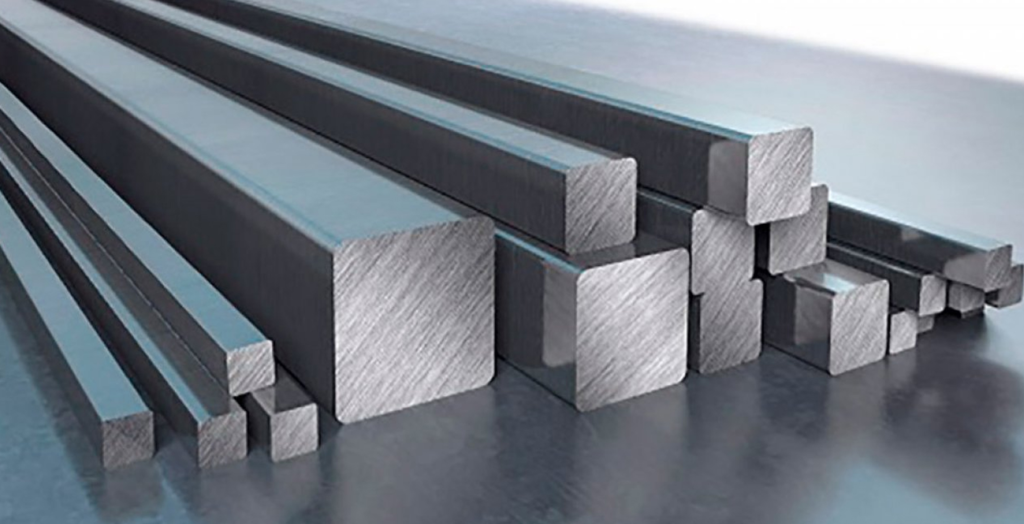

Square bars are long, solid metal bars with a square cross-section. They are commonly made from various materials, including steel, aluminum, and brass. Due to their versatility and strength, square bars are used in a wide range of applications, from construction to automotive manufacturing.

Common Uses of Square Bars

- Construction: Square bars are often used as support beams and structural elements in buildings and bridges.

- Manufacturing: These bars are essential in the production of machinery parts and tools.

- Furniture Making: Square bars are popular in crafting modern and industrial-style furniture.

- Automotive Industry: They are used in the fabrication of various automotive parts.

Understanding the basics of square bars and their applications helps you appreciate the importance of selecting the right ones for your project.

Tip 1: Determine the Material You Need

Different Materials and Their Properties

Square bars come in various materials, each with unique properties suitable for specific applications:

- Steel: Known for its strength and durability, steel is ideal for construction and heavy-duty applications.

- Aluminum: Lightweight and resistant to corrosion, aluminum is perfect for projects where weight is a concern.

- Brass: With excellent corrosion resistance and aesthetic appeal, brass is often used in decorative and plumbing applications.

- Stainless Steel: This material offers superior corrosion resistance and strength, making it suitable for outdoor and marine environments.

Choosing the Right Material for Your Project

When selecting square bars, consider the specific needs of your project. If you need a material that can withstand heavy loads, steel or stainless steel might be your best bet. For projects requiring lightweight materials, aluminum is an excellent choice. Understanding the properties of each material ensures you choose the right square bars for your project’s demands.

Tip 2: Check the Quality Standards

Importance of Quality Standards

Quality standards ensure that the square bars you purchase meet specific criteria for strength, durability, and performance. Adhering to these standards guarantees that the materials will perform reliably in your application.

Common Quality Standards to Look For

- ASTM (American Society for Testing and Materials): ASTM standards specify the mechanical properties and dimensions of square bars.

- ISO (International Organization for Standardization): ISO standards ensure the quality and safety of materials used globally.

- EN (European Standards): EN standards are widely accepted in Europe and cover various aspects of material quality.

How to Verify Quality Standards

When purchasing square bars, ask the supplier for documentation that proves compliance with these standards. This documentation should include test reports and certifications. Ensuring that your square bars meet recognized quality standards is crucial for the success and safety of your project.

Tip 3: Evaluate the Supplier’s Reputation

Why Supplier Reputation Matters

The reputation of the supplier plays a significant role in the quality of the square bars you receive. A reputable supplier is more likely to provide high-quality materials and reliable customer service.

Researching Suppliers

- Online Reviews: Look for reviews and testimonials from other customers. Positive reviews indicate a supplier’s reliability and quality.

- Industry References: Ask for references from industry professionals who have used the supplier’s products.

- Years in Business: A supplier with many years of experience is likely to have a proven track record of delivering quality materials.

Questions to Ask Suppliers

When contacting suppliers, ask the following questions to gauge their reliability:

- Do you provide quality certifications?

- What is your return policy for defective materials?

- Can you provide references from previous customers?

Choosing a reputable supplier ensures you receive high-quality square bars and excellent customer service.

Tip 4: Inspect the Bars Before Purchase

Importance of Visual Inspection

Inspecting the square bars before purchase is essential to ensure they meet your quality expectations. Visual inspection can help you identify any obvious defects or inconsistencies.

What to Look for During Inspection

- Surface Finish: Check for a smooth and uniform surface without cracks, dents, or rust.

- Dimensions: Ensure the bars meet the specified dimensions and tolerances.

- Straightness: Verify that the bars are straight and not warped or bent.

- Labeling: Look for proper labeling that indicates material type, grade, and manufacturer.

Conducting a Thorough Inspection

If possible, visit the supplier’s facility to inspect the square bars in person. If an in-person visit is not feasible, request detailed photographs and documentation from the supplier. Conducting a thorough inspection helps you avoid purchasing defective or substandard materials.

Tip 5: Consider the Cost and Availability

Balancing Cost and Quality

While it might be tempting to choose the cheapest option available, it’s important to balance cost with quality. Low-cost square bars may compromise on material quality and durability, leading to potential failures in your project.

Factors Affecting Cost

- Material Type: Different materials have varying costs. For example, stainless steel is generally more expensive than regular steel.

- Quality Standards: Bars that meet higher quality standards may come at a premium price.

- Supplier Reputation: Reputable suppliers might charge more due to their established quality and service.

Ensuring Availability

Ensure that the square bars you need are readily available from your supplier. Delays in material availability can halt your project and lead to increased costs.

Tips for Cost-Effective Purchasing

- Bulk Purchasing: Buying in bulk can reduce the cost per unit.

- Supplier Negotiation: Negotiate with suppliers for better pricing, especially for large orders.

- Alternative Suppliers: Compare prices from different suppliers to find the best deal without compromising on quality.

By considering both cost and availability, you can select high-quality square bars that fit your budget and project timeline.

Conclusion

Choosing high-quality square bars is crucial for the success and longevity of your project. By understanding the different materials, checking quality standards, evaluating supplier reputation, inspecting the bars before purchase, and balancing cost and availability, you can make an informed decision. High-quality square bars not only ensure the structural integrity of your project but also save you time and money in the long run. Remember, investing in quality materials is an investment in the durability and reliability of your work.

For more insightful articles related to this topic, feel free to visit blooketlogin.pro